Wehrmacht Mechanics Captured a GMC Truck… Then Realized Germany Was Doomed

.

.

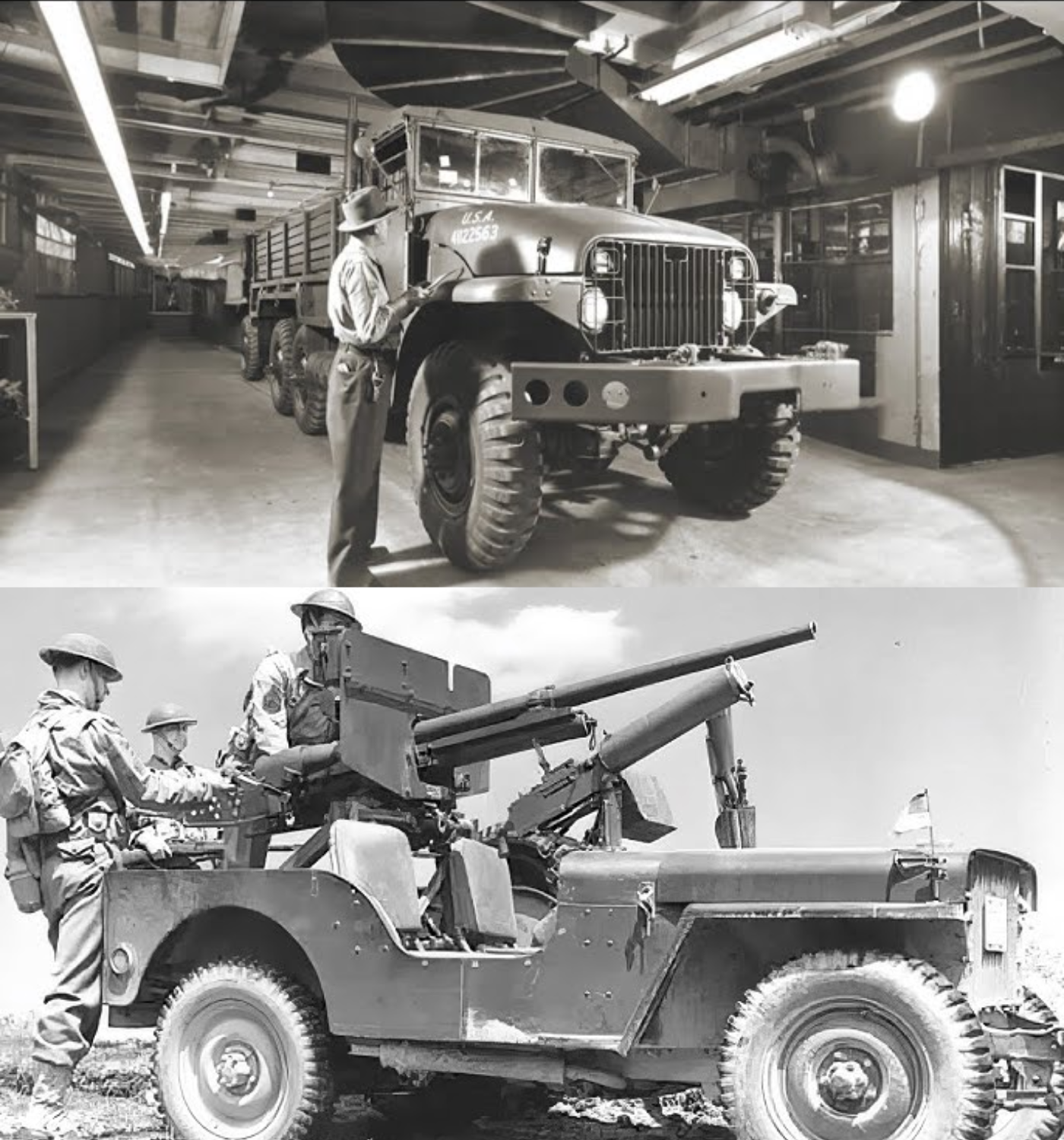

It was August 17th, 1944, in Northern France near the small town of Files. The air was thick with tension as the remnants of an American convoy lay scattered along the roadside, their vehicles abandoned in the wake of a sudden Luftwaffe strafing run. Among the wreckage sat a GMC CCKW truck, its canvas cover torn by shrapnel, the engine still warm from the chaos of battle. This truck, a symbol of American industrial might, would soon become a pivotal lesson for the German mechanics of the 276th Infantry Division.

As the smoke cleared, a group of Wehrmacht mechanics cautiously approached the captured vehicle. “Get the Hopfeld Weeble,” one called out, recognizing that this truck was intact and could provide valuable insights. What they discovered over the next hour would shatter their preconceived notions about warfare and manufacturing.

The mechanics examined the GMC with a mix of curiosity and disbelief. It was massive, dwarfing their standard Opal Blitz trucks. But what struck them most was the simplicity of its design. The six-cylinder engine was easily accessible, with parts clearly labeled in English. One mechanic opened the toolbox mounted on the running board to find standard wrenches and a manual printed on quality paper, filled with detailed illustrations. “Look at this,” the Hopfeld Weeble said, flipping through the manual. “Everything is explained with pictures. A child could follow these instructions.”

They had captured American trucks before, but never one so thoroughly designed for ease of use. The GMC bore markings indicating it was a 1943 model CCKW353, one of thousands produced at the Pontiac plant. As they inspected its components, the true brilliance of American engineering began to dawn on them. The mechanics quickly realized that this truck wasn’t just a vehicle; it was a testament to a philosophy of mass production designed for wartime realities.

“This is designed for idiots,” one mechanic muttered, to which the Hopfeld Weeble corrected him, “No, it’s designed for an army of millions where most men aren’t mechanics. This is brilliant.” The GMC was engineered not for perfection but for practicality. Every bolt was the same size, every nut could be turned with the same wrench. The oil filter could be changed without tools, and the simple six-wheel drive system could engage the front axle with a single lever.

As they continued their inspection, the mechanics noted how the GMC’s design anticipated the harsh conditions of war. The suspension, made of basic leaf springs, was crude but unbreakable. “These could be hammered straight with a rock if necessary,” one mechanic thought, contrasting it with the sophisticated torsion bar suspension of their Opal trucks, which required specialized tools to repair.

The grim realization set in as they calculated the numbers. The truck was stamped with the Pontiac plant number, revealing it was one of approximately 150,000 built in 1943 alone. The supply officer, who had previously worked at the Opal plant in Brandenburg, joined the inspection and offered a somber assessment: “We’re looking at this wrong. This isn’t just a simple truck; it represents an entire manufacturing philosophy we can’t match.”

He explained how the GMC revealed the stark differences between American and German production methods. The stamped steel body panels were crude yet could be produced in vast quantities by any press shop. The wooden cargo bed used standard lumber, and the canvas top was made of commercial fabric. Everything was abundant and easily sourced. “Their strength is in mass production,” he concluded, his voice heavy with realization. “In 1943, we produced approximately 27,000 Opal Blitz trucks. The Americans probably built 20 times that number of these GMC trucks alone.”

Over the next week, the unit utilized the captured GMC for supply runs, transforming their operational capabilities. Where their Opal trucks struggled through muddy farm roads, the GMC powered through with ease. A supply sergeant who drove it daily remarked, “This truck is reliable in a way our vehicles aren’t. It’s built expecting abuse.” The mechanics began to understand that American engineers had designed the GMC for the reality of war, not the theory of it.

On August 25th, 1944, as the Red Ball Express began operations, the German division witnessed something that would further cement their understanding of American logistics. An American convoy passed on a parallel road, a supply column stretching endlessly toward the horizon. “Where are their horses?” a young soldier asked, bewildered. The Hopfeld Weeble realized the boy had never seen a fully motorized army. In contrast, their division relied heavily on horses, which required constant care and limited their mobility.

The supply officer continued his calculations that night. With each American division having approximately 2,000 trucks and 40 divisions in France, he estimated there were 80,000 trucks supporting combat operations. “We have 3 million horses across all fronts and maybe 100,000 trucks,” he lamented. The painful truth was that American automotive plants had been designed for mass production long before the war. When the call to arms came, they simply converted civilian production to military needs.

As the months passed, the division captured more GMC trucks and Dodge WC63s. The mechanics were astonished to find that parts were interchangeable not just between GMC trucks, but across different manufacturers. This standardization meant that any mechanic could service any truck, and any parts depot could supply any vehicle. “Their logistics are unified in a way ours have never been,” the supply officer remarked, recognizing the logistical nightmare faced by the Wehrmacht.

By October 1944, the division’s remaining vehicles became stranded when fuel supplies failed to arrive. The horses could forage for food, but the trucks sat immobile. Meanwhile, American operations continued unabated, their supply network built on thousands of GMC trucks delivering fuel reliably to forward units. The mechanics spent their enforced idleness studying the captured trucks, absorbing the lessons of American industrial philosophy.

One mechanic made an observation that crystallized their understanding: “We designed our vehicles to be good. They designed theirs to be good enough, but in overwhelming numbers, in total war, that wins.” The Hopfeld Weeble wrote a detailed technical report on the GMC CCKW, documenting its robust construction and simple maintenance procedures. He concluded that American vehicle production represented an industrial capacity Germany could not match.

As the war dragged on and the Ardennes offensive commenced, the 276th Infantry Division found themselves using their collection of captured American trucks alongside their dwindling fleet of Opal vehicles. The irony was bitter; Germany’s last major offensive relied on capturing the very vehicles that symbolized why they were losing. When the offensive stalled, it became clear: German logistics had collapsed.

By January 1945, as American forces advanced, the captured GMC trucks proved invaluable. They continued to run, while the Opal trucks had mostly broken down. The difference lay not just in maintenance, but in design philosophy. The GMC was built to absorb punishment, while the Opel was built to German standards of precision that could not withstand the rigors of war.

On April 18th, 1945, the division surrendered. As they were transported to processing centers in American GMC trucks, the mechanics reflected on the lessons learned. They had believed in German superiority, but the war had taught them otherwise. The Americans had built adequate equipment in overwhelming numbers, prioritizing reliability over sophistication.

Months later, as they worked alongside American soldiers in motor pools, the German mechanics absorbed the final lessons of American industrial philosophy. They learned that in modern warfare, perfection was the enemy of good enough. The GMC CCKW was not just a truck; it was a testament to the power of mass production and standardization.

As they returned to a devastated Germany, the mechanics carried with them the lessons of the war. They understood that the future of their industry lay in adopting the principles they had observed. The GMC CCKW had taught them that quantity had a quality all its own, and that the systems behind production could shape the fate of nations.

In the years that followed, German automotive manufacturers began to merge their precision engineering with American mass production techniques. The lessons learned from the GMC CCKW would influence German manufacturing for generations, transforming a defeated enemy into a prosperous ally.

The story of the mechanics who examined that first captured GMC truck in August 1944 is ultimately one of humility and enlightenment. They had seen the future and recognized their past mistakes. The knowledge they gained from the American trucks would shape their nation’s recovery, proving that sometimes, the greatest lessons come from the most unexpected places.